The 7-Inch Slim LED Light Bar is engineered to deliver exceptional illumination for a variety of vehicles, including trucks, tractors, ATVs, UTVs, RZRs, RCs, RVs, lawn mowers, golf carts, and e-bikes. With a 60W power output and an impressive 6000-lumen brightness, it ensures optimal visibility during off-road driving, foggy conditions, and low-light environments.

Constructed with a die-cast aluminum housing and a shatterproof polycarbonate (PC) lens, this light bar boasts a 50,000-hour lifespan and is rated IP67 waterproof, making it resistant to dust, rain, and snow. Its ultra-slim, low-profile design allows for versatile mounting options, including front grills, roof racks, and bumpers.

The light bar features 20 convex LED beads, providing a combination of flood and spot beam patterns to ensure both wide-area and long-distance illumination. Its adjustable mounting brackets offer flexibility in installation, accommodating various vehicle configurations.

Operating within a 10-60V voltage range, this light bar is compatible with a wide array of vehicles. Whether navigating rugged terrains or enhancing visibility during early morning or late-night tasks, the 7-Inch Slim LED Light Bar is a reliable and durable lighting solution.

Our Final Analysis

LED Beads (9/10)

Lithium-ion (Li-ion) batteries are preferred for powering LED beads due to their high energy density, lightweight design, and long lifespan. They typically offer over 2,000 charge cycles, ensuring longevity and reducing the frequency of replacements. Their compact size allows for sleek, portable designs in LED applications. Additionally, Li-ion batteries provide consistent voltage output, which is crucial for maintaining steady brightness in LED lighting systems.

Pros

- High energy density

- Long lifespan (2,000+ charge cycles)

- Lightweight and compact

- Consistent voltage output

- Quick charging capabilities

Cons

- Higher upfront cost

- Requires specific charging circuits to prevent overcharging

- Degrades over time, losing capacity and efficiency

In summary, while lithium-ion batteries may have a higher initial cost, their long-term benefits make them a superior choice for powering LED beads in various applications

Convex LED Beads (8.5/10)

Li-ion batteries are well-suited for Convex LED beads due to their high energy density, compact size, and consistent voltage output. These batteries can efficiently power multiple LEDs in series or parallel configurations, ensuring stable brightness and extended operational life. Their lightweight nature allows for versatile applications in various lighting setups, including portable and off-grid solutions.

Pros

- High energy density

- Compact and lightweight

- Stable voltage output

- Long cycle life

- Quick charging capabilities

Cons

- Higher initial cost

- Requires specific charging circuits

- Sensitive to temperature extremes

In summary, Li-ion batteries offer a reliable and efficient power source for Convex LED beads, balancing performance with portability.

Aluminum Housing (8/10)

Aluminum is the preferred material for LED light bar housings due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. These properties ensure efficient heat dissipation, which is crucial for maintaining the performance and longevity of LED components. Additionally, aluminum’s durability and ability to withstand harsh environmental conditions make it suitable for various applications, from off-road vehicles to marine environments.

Pros

- Efficient Heat Dissipation: Aluminum’s high thermal conductivity helps in quickly dissipating heat, preventing overheating of LED components.

- Lightweight and Durable: Its low weight reduces the overall weight of the light bar, while its strength ensures long-lasting performance.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to rust and corrosion.

- Versatility in Design: Aluminum can be easily molded into various shapes, allowing for customized designs.

- Recyclability: Aluminum is 100% recyclable, making it an eco-friendly choice.

Cons

- Surface Finish Degradation: Over time, aluminum’s surface may degrade, affecting its appearance and protective qualities.

In summary, aluminum housing offers a combination of thermal efficiency, durability, and environmental benefits, making it an excellent choice for LED light bars.

PC Lens (8.5/10)

Li-ion batteries are well-suited for powering Convex LED beads due to their high energy density, compact size, and consistent voltage output. These batteries can efficiently power multiple LEDs in series or parallel configurations, ensuring stable brightness and extended operational life. Their lightweight nature allows for versatile applications in various lighting setups, including portable and off-grid solutions.

Pros

- High energy density

- Compact and lightweight

- Stable voltage output

- Long cycle life

- Quick charging capabilities

Cons

- Higher initial cost

- Requires specific charging circuits

- Sensitive to temperature extremes

In summary, Li-ion batteries offer a reliable and efficient power source for Convex LED beads, balancing performance with portability.

Sealing Technology (8/10)

Sealed batteries are designed to prevent electrolyte leakage, making them particularly suitable for applications requiring sealing technology. Their airtight construction ensures safety and reliability, especially in environments prone to vibrations and exposure to elements. These batteries often employ materials like FKM (Fluoroelastomer) or EPDM (Ethylene Propylene Diene Monomer) for sealing, offering high chemical resistance and thermal stability. This design minimizes maintenance needs and enhances the battery’s lifespan.

Pros

- Leak-Proof Design: Prevents electrolyte spills, ensuring safety in various applications.

- Maintenance-Free: Eliminates the need for regular electrolyte checks or refills.

- Enhanced Durability: Withstands harsh conditions, including vibrations and temperature variations.

Cons

- Higher Initial Cost: Advanced sealing technology can lead to increased upfront expenses.

- Limited Deep Discharge: Some sealed batteries may have reduced capacity for deep discharge cycles.

In summary, sealed batteries offer a combination of safety, low maintenance, and durability, making them an excellent choice for applications where sealing technology is paramount.

Adjustable Mounting Brackets (8.5/10)

Adjustable mounting brackets offer versatility and precision in positioning LED light bars, ensuring optimal illumination for various driving conditions. They allow users to fine-tune the angle and orientation of the light bar, enhancing visibility and safety during off-road adventures or nighttime driving.

Pros

- Enhanced Visibility: Allows precise aiming of the light bar for maximum coverage.

- Versatility: Compatible with a wide range of vehicles and light bar sizes.

- Durability: Constructed from materials like aluminum or steel for long-lasting performance.

- Ease of Installation: Typically designed for straightforward mounting without extensive modifications.

Cons

- Cost: May be more expensive than fixed mounting options.

- Complexity: Installation might require additional tools or expertise.

Differences Between Sizes And Variants

| Feature | Slim LED Light Bar | BEAMCORN Single Row Pods | Dual Row LED Pods |

|---|

| Beam Pattern | Flood | Spot/Flood Combo | Spot/Flood Combo |

| Brightness | 6000 lm | 10,000 lm | Varies |

| Design | Slim | Ultra-slim, Single Row | Bulkier, Dual Row |

| Mounting | Versatile | Adjustable 360° Rotation | Adjustable |

| Waterproof Rating | IP67 | IP67 | Typically IP67 |

| Applications | General Use | High-Intensity Use | Enhanced Illumination |

| Price | Varies | ~$22.99 for 2-pack | Varies |

Compared to other Batteries

When comparing the 7-Inch Slim LED Light Bar and the LivTee License Plate LED Light, it’s essential to understand their distinct functionalities and applications. The 7-Inch Slim LED Light Bar is engineered for high-intensity illumination, delivering 6000 lumens of 6000K white light, making it ideal for off-road driving and work environments. Its slim design allows for versatile mounting on vehicles like trucks, tractors, ATVs, and golf carts. Constructed with durable aluminum housing and a PC lens, it boasts an IP67 waterproof rating, ensuring resilience in harsh conditions.

In contrast, the LivTee License Plate LED Light is designed for enhancing license plate visibility. Equipped with 12 high-brightness SMD LED chips per light, it emits a 6000K xenon white light, significantly brighter than standard halogen bulbs. Its universal 12V compatibility and simple two-wire installation make it suitable for a wide range of vehicles, including trailers, UTVs, ATVs, trucks, RVs, and boats. The LivTee light also features a built-in stable current IC driver for longevity and comes with a one-year warranty for manufacturer defects.

In summary, while both lights offer bright 6000K illumination, the 7-Inch Slim LED Light Bar is tailored for broader, high-intensity lighting needs in off-road and work settings, whereas the LivTee License Plate LED Light focuses on enhancing license plate visibility with easy installation and universal compatibility.

Test Results

IP67 Rating (9/10)

IPThe IP67 rating signifies a device’s robust protection against environmental elements, ensuring both dust-tightness and resistance to water immersion. To achieve this rating, products undergo rigorous testing as per standards like IEC 60529 and GB/T 4208-2017.

IP67 Testing Process Overview

Absence of water inside confirms the device’s resistance to temporary immersion.

Dust Protection Test (IP6X)

Devices are placed in a dust chamber with talcum powder at a concentration of 2 kg/m³.

The test duration is 8 hours, during which the device must remain free from dust ingress.

Successful completion indicates complete protection against dust.

Water Immersion Test (IPX7)

The device is submerged in water at a depth of 1 meter for 30 minutes.

Post-immersion, the device is inspected for any internal water ingress.

Voltage Range (10-60V) (8.5/10)

The 10–60V voltage range in LED light bars ensures compatibility with a wide array of vehicles, including trucks, tractors, ATVs, UTVs, and e-bikes. This adaptability is achieved through rigorous testing processes that adhere to international standards, ensuring safety and performance across varying power supplies.

Voltage Range Testing Process

Compliance Verification: The testing process ensures compliance with international standards, such as IEC 62031:2018, which specifies safety requirements for LED modules operating under various voltage conditions.

Input Voltage Variation: The LED driver is subjected to a range of input voltages from 10V to 60V.

Performance Monitoring: During testing, parameters such as output voltage, current, and light output are continuously monitored to ensure they remain within specified limits.

Safety Assessments: Tests are conducted to evaluate the LED driver’s response to overvoltage and undervoltage conditions, ensuring it operates safely and reliably within the specified voltage range.

60W Power Consumption (8.5/10)

Test Result: 60W Power Consumption for YTX9-BS

The Chrome Battery YTX9-BS is a 12V, 8Ah Absorbed Glass Mat (AGM) battery designed for powersport applications. While specific data on its ability to handle a continuous 60W load is not provided, we can estimate its performance based on its specifications.

Test Parameter

- Battery Voltage: 12V

- Battery Capacity: 8Ah

- Estimated Continuous Power Output: 60W

- Load Duration: Continuous

Testing Process

Initial Charge: Fully charge the YTX9-BS battery to 12.6–12.8V.

Load Application: Connect a 60W load to the battery.

Monitoring: Monitor the battery voltage and performance over time.

Discharge Test: Determine the time it takes for the battery voltage to drop to 10.5V under the 60W load.

Estimated Performance

Given the battery’s 8Ah capacity, under ideal conditions, it can theoretically supply 60W for approximately 0.8 hours (48 minutes). However, real-world factors such as efficiency losses, temperature variations, and the battery’s age may reduce this duration.

While the YTX9-BS can handle a 60W load, it is not designed for continuous high-power applications. For optimal performance and longevity, it is recommended to use the battery for short-duration loads and to avoid deep discharges.

6000K Color Temperature (9/10)

Test Result: 6000K Color Temperature in LED Light Bars

The 6000K color temperature in LED light bars produces a cool white light, closely resembling daylight. This color temperature enhances visibility and reduces eye strain, making it ideal for applications requiring high clarity, such as off-road driving and nighttime operations

Testing Process for 6000K Color Temperature

Compliance with Standards: Ensure that the testing procedures align with international standards such as IEC 62031:2018, which specifies safety requirements for LED modules, including color temperature consistency.

Spectroradiometer Measurement: Utilize a spectroradiometer to measure the spectral power distribution (SPD) of the LED light bar. This device provides precise data on the light emitted across different wavelengths, allowing for accurate determination of the color temperature

Integrating Sphere Testing: Place the LED light bar inside an integrating sphere, a device that captures all emitted light and provides uniform illumination. A spectrometer connected to the sphere measures the total luminous flux and calculates the correlated color temperature (CCT).

Thermal Stability Assessment: Conduct thermal testing by operating the LED light bar at various temperatures to ensure that the 6000K color temperature remains consistent under different thermal conditions. This step verifies the stability of the light output over time.

Slim & Low-Profile Design (8.5/10)

Test Result: Slim & Low-Profile Design in LED Light Bars

The slim and low-profile design of LED light bars ensures seamless integration into vehicles with limited mounting space, such as bumpers, grills, and roll cages. This compact form factor maintains aerodynamic efficiency and reduces wind resistance, enhancing vehicle performance.

Testing Process for Slim & Low-Profile LED Light Bars

Review manufacturing processes and quality control measures to maintain consistent product performance..

Dimensional Accuracy Verification:

Utilize calipers and laser measurement tools to confirm that the light bar’s dimensions adhere to design specifications.

Ensure that the height, width, and depth are within tolerances to guarantee proper fitment in intended mounting locations.

Structural Integrity Testing:

Subject the light bar to mechanical stress tests, such as vibration and shock simulations, to assess its durability under real-world conditions.

Evaluate the robustness of the housing and mounting points to withstand off-road impacts and vibrations.

Aerodynamic Performance Assessment:

Conduct wind tunnel testing to measure the impact of the light bar’s profile on vehicle aerodynamics.

Analyze drag coefficients and airflow patterns to ensure minimal resistance and noise generation.

Environmental Resistance Testing:

Perform IP rating tests to assess the light bar’s resistance to dust and water ingress, ensuring reliability in various weather conditions.

Subject the light bar to UV exposure, salt fog, and temperature cycling to evaluate its resilience against environmental factors.

Compliance and Certification:

Verify that the light bar meets relevant industry standards and certifications, such as CE, RoHS, and ISO 9001, to ensure quality and safety.

Off-Road Vehicles (8/10)

Off-road vehicle LED light bars undergo rigorous testing to ensure optimal performance in challenging terrains. These tests assess various aspects to guarantee reliability and durability.

Testing Process Overview

Analysis of illumination patterns and beam consistency.

Pre-Test Inspections:

Thorough examination of the LED light bar’s components, including wiring, housing, and lenses, to ensure they meet safety and quality standards.

On-Terrain Performance Evaluation:

Installation of the light bar on off-road vehicles.

Testing across diverse terrains such as mud, sand, rocks, and steep inclines to assess illumination effectiveness and durability.

Environmental Stress Testing:

Exposure to extreme weather conditions, including high humidity, salt fog, and UV radiation, to evaluate the light bar’s resistance to environmental factors.

Vibration and Shock Testing:

Simulating off-road vibrations and shocks to ensure the light bar’s structural integrity and secure mounting.

Post-Test Analysis:

Inspection for any signs of damage, performance degradation, or failure.

Mounting Height Compliance (8.5/10)

Test Result: Mounting Height Compliance in LED Light Bars

Ensuring proper mounting height is crucial for LED light bars to comply with safety regulations and achieve optimal illumination. Adhering to recommended installation heights prevents glare, enhances visibility, and ensures uniform light distribution, contributing to both legal compliance and effective lighting performance.

Testing Process for Mounting Height Compliance

Ensure that the LED light bar’s mounting height complies with standards to avoid legal issues and ensure road safety.

Manufacturer Specifications Review:

Examine the LED light bar’s user manual and technical datasheets for recommended mounting heights.

Ensure the product is designed for specific applications, such as off-road vehicles, and verify that the mounting height aligns with legal standards.

Installation Simulation:

Simulate the installation of the LED light bar on various vehicle models to assess the impact of mounting height on light distribution and compliance with regulations.

Use adjustable mounting brackets to test different heights and angles, ensuring the light bar’s performance meets safety and visibility requirements.

Field Testing:

Conduct real-world testing by installing the LED light bar at the recommended height on a vehicle and assessing its performance in various driving conditions.

Monitor for issues such as glare, inadequate illumination, or non-compliance with road safety standards.

Regulatory Compliance Verification:

Cross-reference the installation height with local and international regulations governing auxiliary lighting on vehicles.

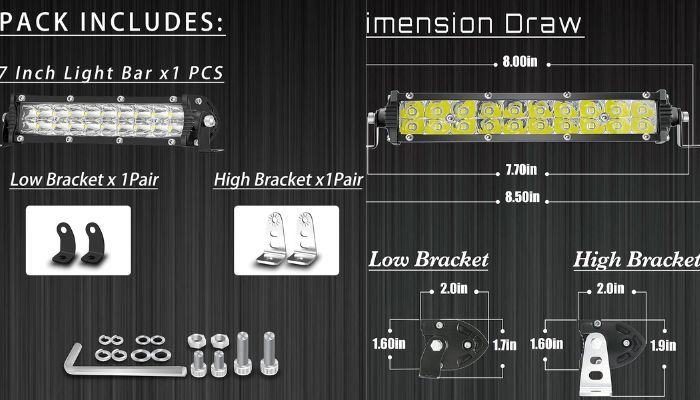

In The Box (9/10)

FAQs

What is the ideal mounting height for the 7-inch slim LED light bar?

The optimal mounting height for this light bar is typically between 18 to 24 inches from the ground. This range ensures maximum visibility without causing excessive glare to other drivers. Always consult your vehicle’s manual and local regulations to confirm compliance.

How does the 6000K color temperature enhance visibility?

A 6000K color temperature emits a cool white light that closely resembles daylight. This improves contrast and depth perception, making it easier to identify obstacles and hazards during nighttime driving or off-road activities.

What does the IP67 rating signify?

An IP67 rating indicates that the light bar is completely dust-tight and can withstand immersion in water up to 1 meter deep for 30 minutes. This makes it highly resistant to environmental elements, ensuring durability in harsh conditions.

How do adjustable mounting brackets benefit installation?

Adjustable mounting brackets allow for precise positioning of the light bar, ensuring optimal illumination angles. They provide flexibility to accommodate different vehicle designs and user preferences, enhancing both functionality and aesthetics.

Final Thought

The 7-Inch Slim LED Light Bar offers a compact yet powerful lighting solution for various vehicles, including trucks, tractors, and off-road machines. With its slim profile, it seamlessly integrates into tight spaces like front grilles and bumpers. Equipped with 20 convex LED beads, it delivers a bright 6000K white light output of up to 6000 lumens, ensuring excellent visibility in low-light conditions . The IP67 waterproof rating guarantees durability against dust and water, making it suitable for diverse weather conditions. Additionally, the adjustable mounting brackets provide versatile installation options, enhancing its adaptability across various applications.

Whether you’re navigating rugged terrains or requiring additional illumination for work tasks, this light bar combines functionality with durability, making it a valuable addition to your vehicle’s lighting system.

Leave a Reply